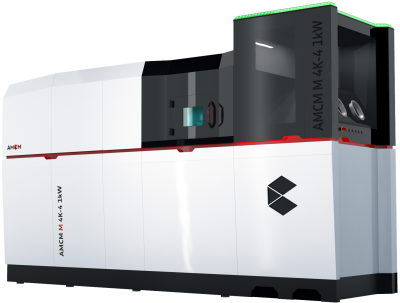

Based on the EOS M 400 series, the customized, high-performance Direct Metal Laser Solidification (DMLS®) printers now in production at AMCM’s newly expanded facility.

New 3D printer available in both one (1) and four (4) laser offerings

Available build volume of 450 x 450 x 1000mm

Rocket manufacturing organizations seen as early adopters

Several M 4K currently in production in the dedicated new production facility in Starnberg

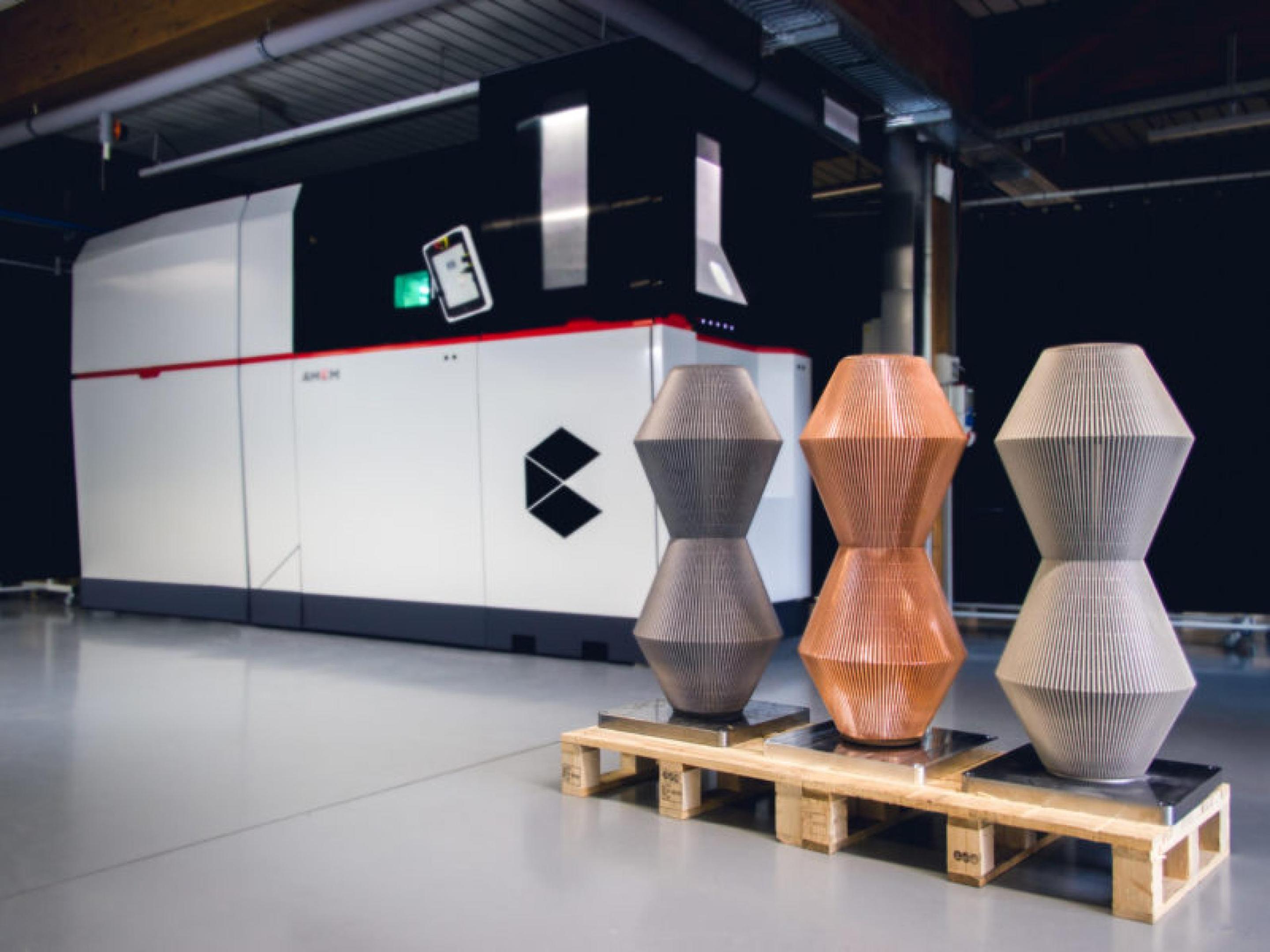

Built on the industry proven EOS M 400 platform, the AMCM M 4K is tailored to produce large applications, with a height up to one meter (39.37 inches). Additional features include increased robustness of the frame design, a new filter system (RFS 2.0), and optional soft recoating. The AMCM M 4K can produce applications from a wide range of materials, including aluminum (AlSi10Mg), nickel alloy (IN718), and copper alloy (CuCr1Zr).

Additional Details of the AMCM M 4K Platform

Large building volume of 450 x 450 x 1,000 mm

Laser Type: Yb Fiber laser: 1 x 1,000 watt, 4 x 400 watt or 4 x 1,000 watt, optional

Wave length: 1,070 nm

Precision Optics: F-theta-lens

Scan Speed during build process: up to 7.0 m/s (23 ft./sec)

Process Gas Cooling: additional gas cooling unit (optional)

Dimensions of complete system: (W x D x H): 193 x 83 x 122 in

Compatible with legacy EOS M 400 Series process parameter sets

Powder handling option for manual or semi-automatic operation

Open software for process optimization with high power laser

Powder bed DMLS 3D printing is used for the most demanding applications – high performance, sophisticated, mission critical parts. With the help of AMCM, Launcher was one such organization that realized very early in the AMCM M 4K’s development that it could now produce – using the preferred DMLS method – its copper alloy E-2 combustion chamber, the world’s largest 3D printed liquid rocket engine. “The AMCM M 4K solved for both our desire to 3D print a tall combustion chamber in a single piece, and produce it in a copper material,” said Launcher CEO, Max Haot. “Printing in a single piece reduces cost and enables the highest-performance regenerative cooling design.” Launcher will be testing E-2 at NASA Stennis as part of an Air Force Phase II SBIR later this year.

The AMCM M 4K platform is a global offering and is available now. AMCM is ramping up its production at their new expanded facility in Starnberg, Germany. In addition to the AMCM M 4K platform, AMCM is pushing the limits of additive manufacturing (AM) technology producing other high-performance, customized industrial 3D printers based on EOS technology. For more information on AMCM, check out the following overview of the M 4K: