1kW

High Energy

Kilowatt system with dual laser setup.

Increased productivity for multiple materials (e.g. Al and Cu) - Excellent part properties e.g. Cu density, electrical conductivity - Compatible with legacy EOS M 290 400 W process parameter sets e.g. same focus, beam quality - Open software for process optimization with high power laser - Ability to pre-develop 1 kW processes on a mid-size platform for later transfer to other single or multi-laser 1 kW platforms (e.g. AMCM M 450 or AMCM M 4K)

-

2xThe 1 kW punch

-

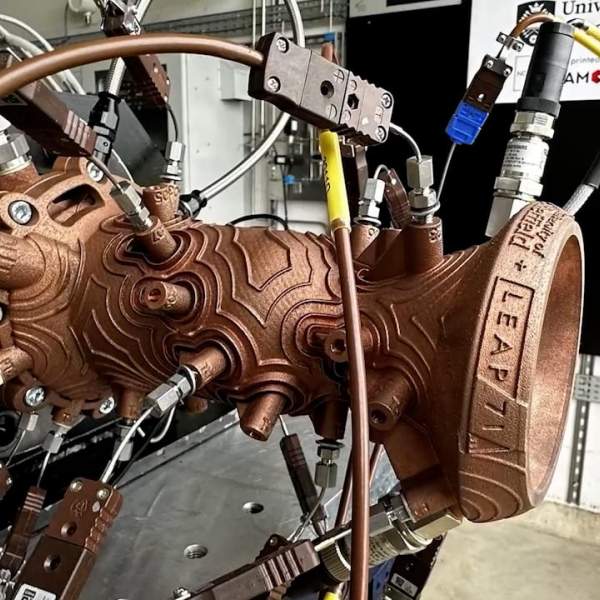

EnablingCopper

-

500° CBuild plate temperature possible with plug-in module

-

30+EOS legacy processes available

The AMCM M 290 kW system with two 1 kW lasers enables innovations in the design of components such as windings for electric motors made of copper with 100 % IACS. The system allows a variety of high power processes for other materials. Of course, all EOS legacy 400W processes run just fine.

Copper Specialist.

The AMCM M 290 kW system with two 1 kW lasers enables innovations in the design of components such as windings for electric motors made of copper with 100 % IACS. The system allows a variety of high power processes for other materials. Of course, all EOS legacy 400W processes run just fine.

Full Field Overlap

Thermal Management

Adapted Laminar Flow

Plug-In Modules

Technical Data

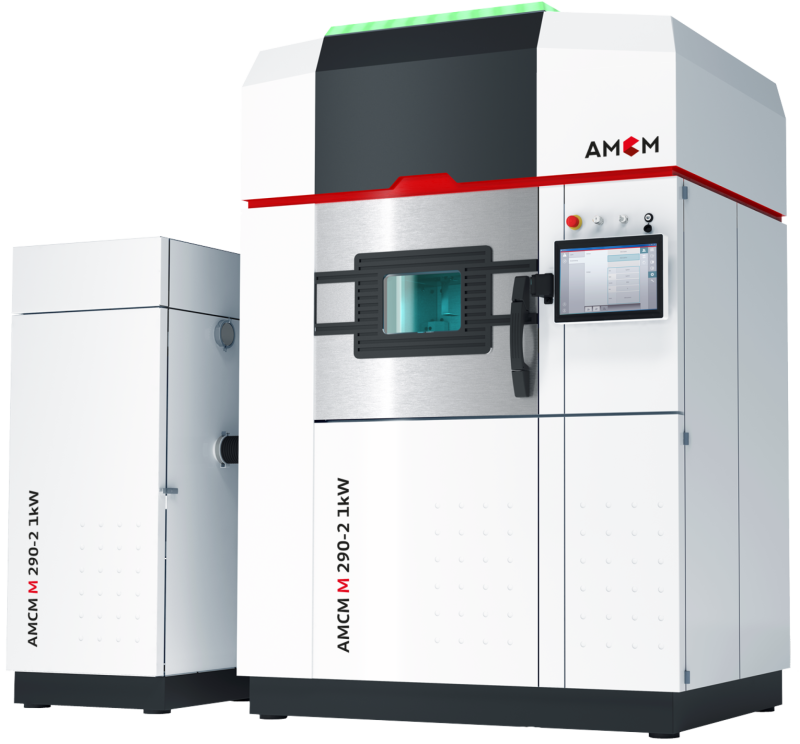

AMCM M 290-2 1kW

| Building volume (W x D x H) | 250 x 250 x 325 mm | 9.85 x 9.85 x 12.8 in (height incl. build plate) |

|---|---|

| Laser type | Yb Fiber laser |

| Nominal power | 2 x 1 kW |

| Wave length | 1070 mm |

| Precision optics | F-theta-lens |

| Scanner | digital scanner with active cooling |

| Scanning speed | up to 7.0 m/s | 23 ft./sec |

| Focus diameter | approx. 85 µm | 0.003 in |

| Process gas cooling | integrated |

| Power supply | 32 A / 400 V |

| Power consumption | 17 kW |

| Inert gas supply | 7,000 hPa; 20 m³/h | 102 psi; 706 ft³/h |

| Dimensions (W x D x H) | 2,680 x 2,120 x 2,400 mm | 105.5 x 83.5 x 94.5 in |

| Recommended installation space | min. 4,800 x 3,600 x 3,500 mm | 189 x 142 x 138 in |

| Weight | approx. 1,350 kg | 2,756 lb |