Starnberg, October 2022 - AMCM (Additive Manufacturing Customized Machines) was founded 5 years ago as an agile start up by EOS to provide the market as quickly as possible with industrial, metal-based 3D printing solutions for new applications that are very specifically tailored to the individual needs of customers. AMCM offers AM solutions with varying degrees of customization based on proven EOS technology and processes. AMCM presents itself at formnext 2022 in hall 11.1/booth C51 in Frankfurt/Main e.g., with the topics "large build volumes", "copper 3D printing" and "finest structures".

Additive copper applications have been the starting point for AMCM's system developments, with the need for faster processes, larger components and more complex geometries being driven primarily by the aerospace industry. However, AMCM is also concerned with ultra-fine structures in the micron range made of materials such as tungsten for the anti-scatter grids used in computer tomographs to achieve greater detail.

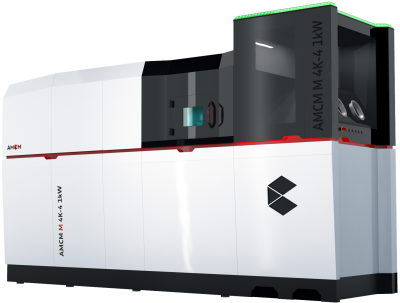

To achieve faster copper processes, AMCM soon turned to powerful fiber lasers that produce excellent results. Driven by the aerospace company Launcher, and others, the AMCM M 4K was developed. The goal was to 3D print combustion chambers in one piece. This enabled a completely optimized design of the internal cooling channels, a reduction in components, process simplification and lower overall costs. It is the first system in the world that can print components up to 1000 mm high. Companies such as Ariane Group also rely on the AMCM M 4K and take the process to the next level.

The main market for AMCM and the large systems has been established in the USA. Well-known aerospace suppliers such as Sintavia and Morf3D serve the high local demand. Much of the equipment is operated directly by OEMs. The 3D-printed combustors with integrated cooling channels achieve a higher power density than conventionally manufactured combustors.

The recent cooperation with Hyperganic, a company involved in the design of components using artificial intelligence, demonstrates the high innovative power of the technology. It is additive manufacturing at the scale developed by AMCM that enables the production of AI-designed aerospike engines with their technological advantages. The component, printed in one piece, has an impressive height of approximately 800 mm. The AMCM M 4K makes the most complex internal structures for components up to 1000 mm possible in the first place. The market is already signaling the neet to print even larger components.

"We are rising to this challenge and are pushing ahead with further development based on the AMCM M 4K".

— Martin Bullemer, Managing Director AMCM