Starnberg, 13th May, 2024 – The MTC, based in Coventry UK, is an independent Research & Technology Organization, providing customers with easy and early access to the latest applied technologies and research. The MTC is the National Center of Additive Manufacturing in the UK and is a focal point for AM research activities within the country. The team specializes in developing advanced manufacturing processes and technologies to produce complex and large-scale AM components. MTC wanted a system that was flexible, industrially scalable and pushed the boundaries to enable step changes in novel materials development and productivity.

Using smarter lasers not more

AMCM, whose sister company EOS recently joined MTC as a Tier 3 member, provides customized solutions beyond state-of-the-art standard systems based on industrialized EOS systems. The AMCM M 290-2 FLX incorporates two nLIGHT AFX lasers, offering a variable laser spot from 85 µm Gaussian to 210 µm donut shape. This enables a wider and shallower melt pool with more uniform temperature distribution, resulting in faster printing with improved process stability, reduced soot, and spatter. The traditional approaches that have been used to date to solve these problems, such as beam defocusing, can have a detrimental effect on the focus profile and a negative impact on part quality and repeatability.

The AMCM M 290-2 FLX offers a full field overlap, meaning both scanners can reach all spots on the build plate and full flexibility is possible with regards to build orientation. AMCM already showed a significant productivity increase with for example IN718 material. Compared to a standard single 400W laser process with 85 µm spot size, a single nLIGHT exposure process is 2 times faster in addition to having the same mechanical and surface properties, this is expected to be further improved with an additional laser source.

Prepared for most demanding materials

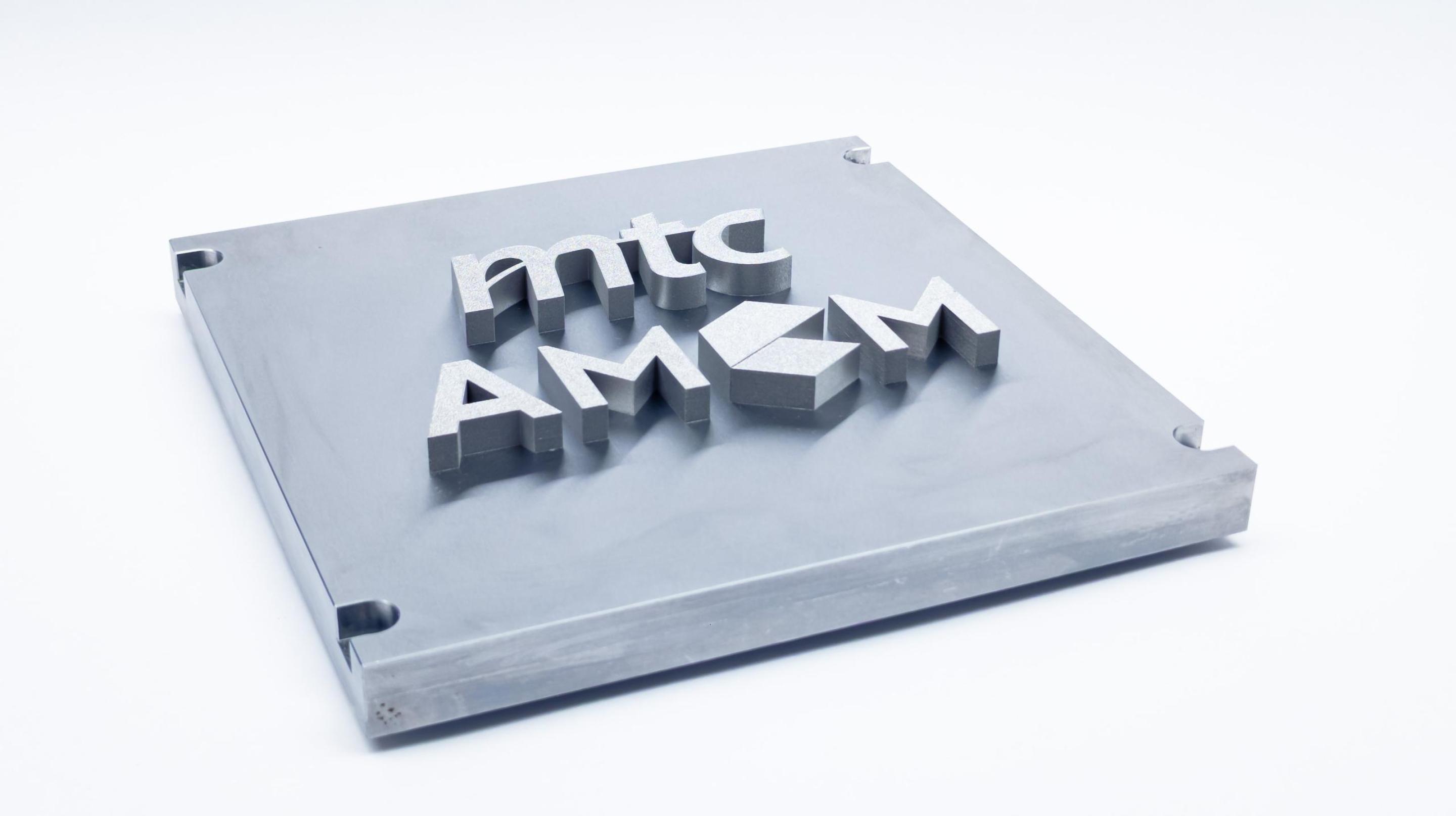

Gas flow and oxygen level are often the defining factors in PBF-LB processes quality. This is particularly true when speed is increased above a certain threshold or when oxidation-sensitive materials are used. As AMCM specializes in industrial solutions, its systems feature unique long term stable atmosphere control at < 50 ppm. MTC will initially use the AMCM M 290-2 FLX for a comprehensive evaluation of pure copper printing, which is a challenging material when aiming for industrial quality and reliability.

Furthermore, the AMCM system can heat the build platform up to 500°C. As pre- and post-heat treatment is critical in the processing of certain high performance aluminum alloys and refractory metals, this enables MTC to evaluate a wide range of high-end applications, such as those in the aerospace and defence industry.