Additive manufacturing technologies like Laser Powder Bed Fusion (LPBF), Directed Laser Deposition (DLD) and others are pivotal for producing large-scale metal parts, but each faces unique challenges in scaling build sizes. LPBF excels in precision and detail, making it ideal for intricate components, yet expanding build areas to 1m x 1m and beyond demands robust gas flow management to maintain quality. Competing methods like DLD can produce larger parts but often sacrifice fine details and require additional post-processing.

AMCM introduces the M 8K with AirSwordTM Gas Flow Technology

AMCM set out to overcome the airflow-related scalability challenge while preserving the speed and reliability of the industry-proven fixed scanner approach. Traditional gas flow methods often struggle in larger spaces, resulting in uneven distribution, turbulence and suboptimal outcomes. However effective gas flow is essential for removing by-products such as spatter and soot, maintaining an inert environment and ensuring the production of high-quality parts especially on ultra-long builds.

With the M 8K and the upcoming M 10K, AMCM introduces the AirSwordTM gas flow concept. A precision-engineered gas flow management system was designed to elevate the performance of large-format LPBF machines. This is achieved through combining the unmatched speed and precision of fixed scanner systems with a fundamentally revised gas flow approach.

Defeating Laser-Smoke Interaction with AirSwordTM Concept

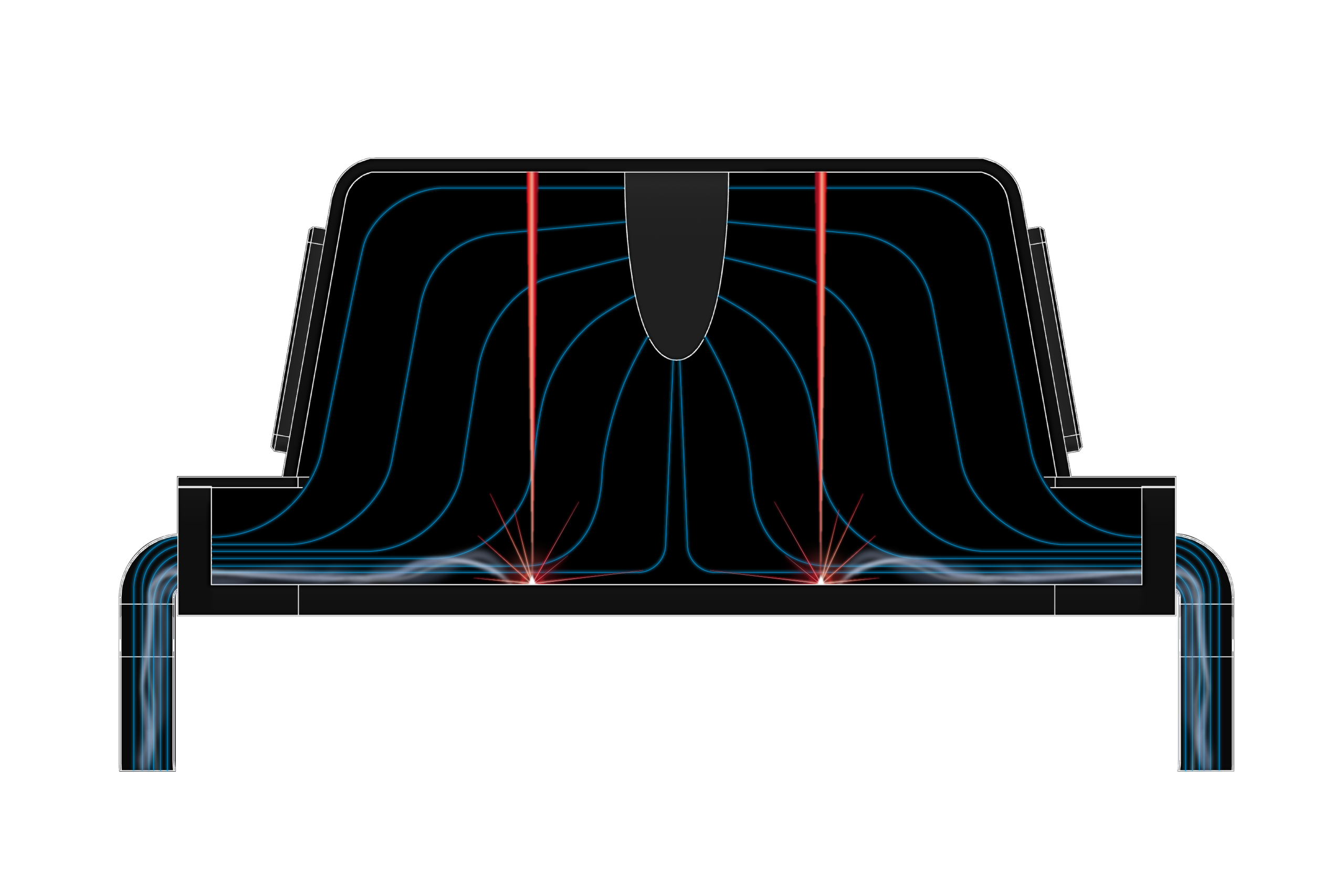

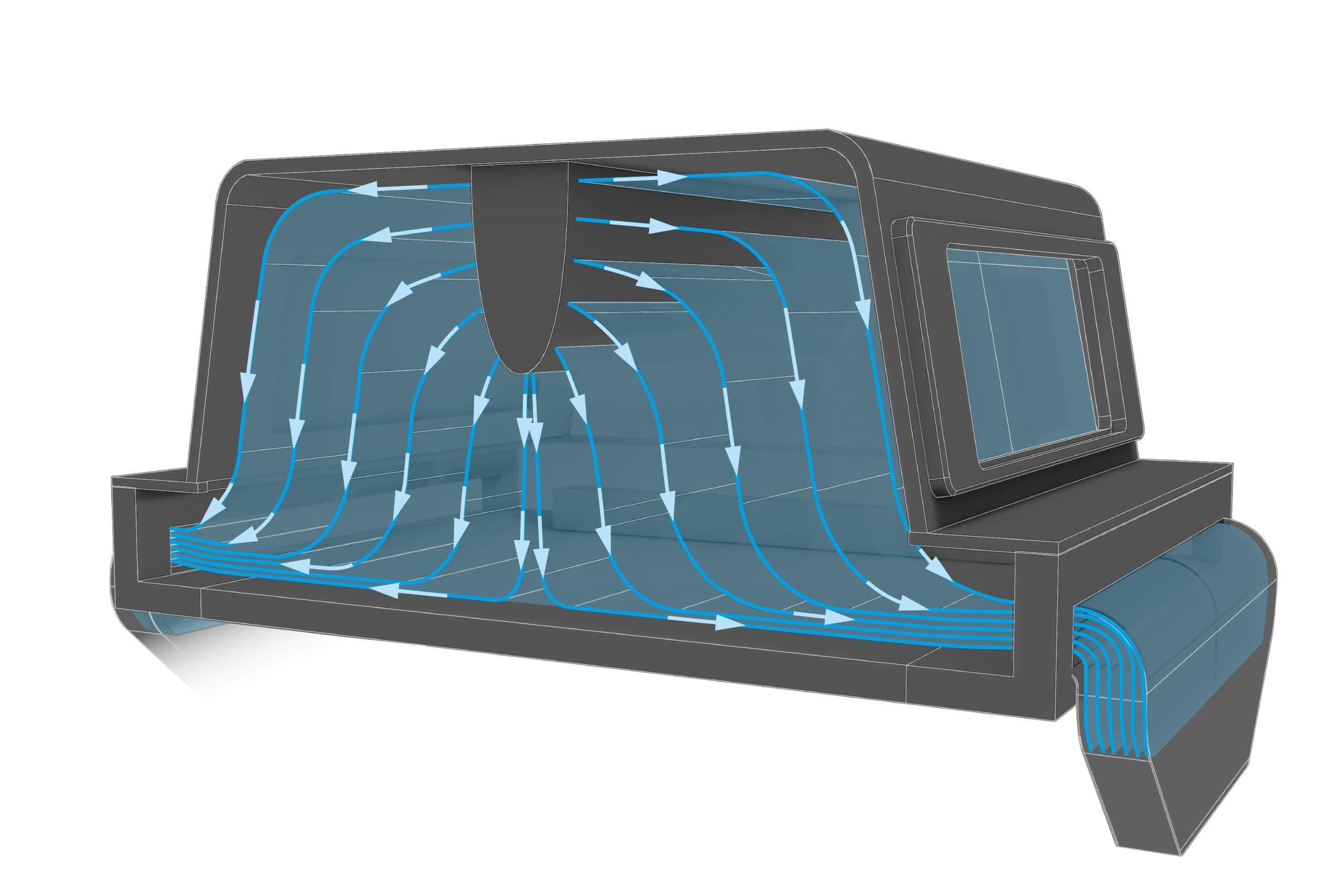

The AirSwordTM introduces a dynamic, multi-layered, and seamless gas flow that spans across the entire building area. This flow actively pushes smoke and soot directly toward the exhaust, maintaining optimal process conditions even in large chambers like those of the M 8K and the upcoming M 10K.

At the heart of the system is a central gas-emitting device that splits the flow into two opposing streams along the chamber’s axis. The key advantage of this design is that smoke from the simultaneously generated melt pools neither reaches the opposite side nor linger at the point of origin - eliminating any possibility of laser-smoke interaction. Instead, the smoke is extracted sideways for each half, ensuring a clean, interference-free process.

Another critical benefit of the AirSwordTM concept is its ability to keep cover glasses and the laser travel path free from smoke, a persistent challenge in long-duration LPBF print jobs. Accumulated soot and vapor plumes can degrade laser quality and part precision over time. AirSwordTM’s ceiling-directed stream efficiently clears the area in front of the optics, ensuring clear laser paths and consistent performance throughout extended builds.

The AirSwordTM with its multi-layered flow architecture, significantly reduces maintenance downtime and boosts productivity - making it an ideal solution for high-volume, long-term manufacturing.

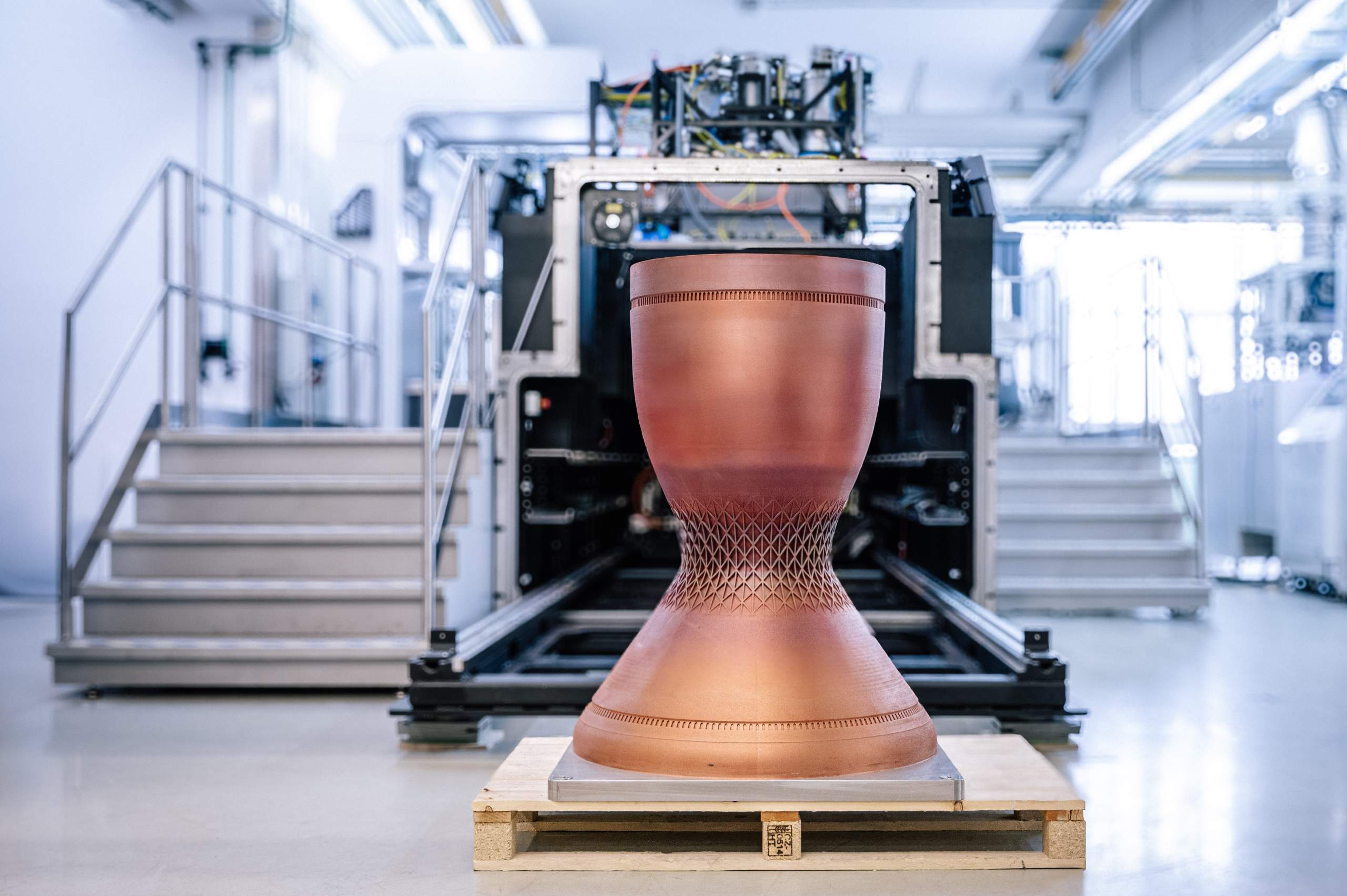

“We designed the AirSwordTM concept using extensive Computational Fluid Dynamics (CFD) simulations to optimize flow patterns for large LPBF chambers. These simulations guided the design of the flow nozzle outlets and overall flow dynamics. The device itself is manufactured on our M 4K system, leveraging LPBF’s design freedom to create a highly efficient, custom-fit gas flow solution.”

— Georg Fey, Team Manager Application & Innovation AMCM

M 8K, M 10K - Proven Performance Ready to Scale

The M 8K, equipped with eight 1 kW lasers and a 0.7 m² powder bed, enables the production of intricate, high-precision components. It builds on the success of the M 4K introducing new design principals such as the AirSwordTM, offering an 800 x 800 x 1200 mm³ build volume. The system is designed for high-productivity applications and handles up to 5 tons of powder with precision along its z-axis.

AMCM’s vision extends further with even larger systems, such as the M 10K, featuring a 1000 x 1000 mm² build area.

“Designing a system of this size involves a whole range of challenges. The excellent laser, scanner, and optics design, based on decades of process expertise from EOS, ensures reliability. AirSwordTM complements this by maintaining a uniform protective gas atmosphere across the M 8K’s and M 10K’s expansive powder beds, safely dissipating fumes to avoid quality loss over long print times. Integrated with advanced process control technologies like SmartFusion and EOSTATE Exposure OT, AirSwordTM enhances in-process quality assurance, reducing the need for extensive post-build testing. “

— Martin Bullemer, Managing Director AMCM

“There are several concepts how to manage the gas flow over large building envelopes, including mechanically complex systems. We firmly believe that we should stick with a fixed scanner approach combined with optimized airflow for as long as possible, as the advantages in terms of build speed and part quality are unbeatable. Unlike mechanically complex systems AirSwordTM’s streamlined design minimizes failure modes and enhances reliability. Mechanical complexity often introduces software complexity, increasing the risk of errors. With AirSwordTM’s straightforward approach we avoid these pitfalls.“

— Felix Bauer, Head of Sales AMCM